Have difficulty in year-end inventory? Let automated warehouse systems help!

Almost every enterprise will conduct a year-end inventory at the end of the year, which involves raw materials, semi-finished products, finished products, equipment accessories, and other materials. Workers from each department will get involved in.

Inventory is a process of reorganizing, inspecting, and verifying all materials within a company. Generally, it is conducted at least twice a year, and is divided into full inventory and random inventory. The inventory may take 1-2 days, and some may even take a week. The entire inventory process is cumbersome, it has various printed reports and communication, which involves multiple departments. Workers need to spend a lot of physical and mental energy to complete this task, and sometimes make mistakes.

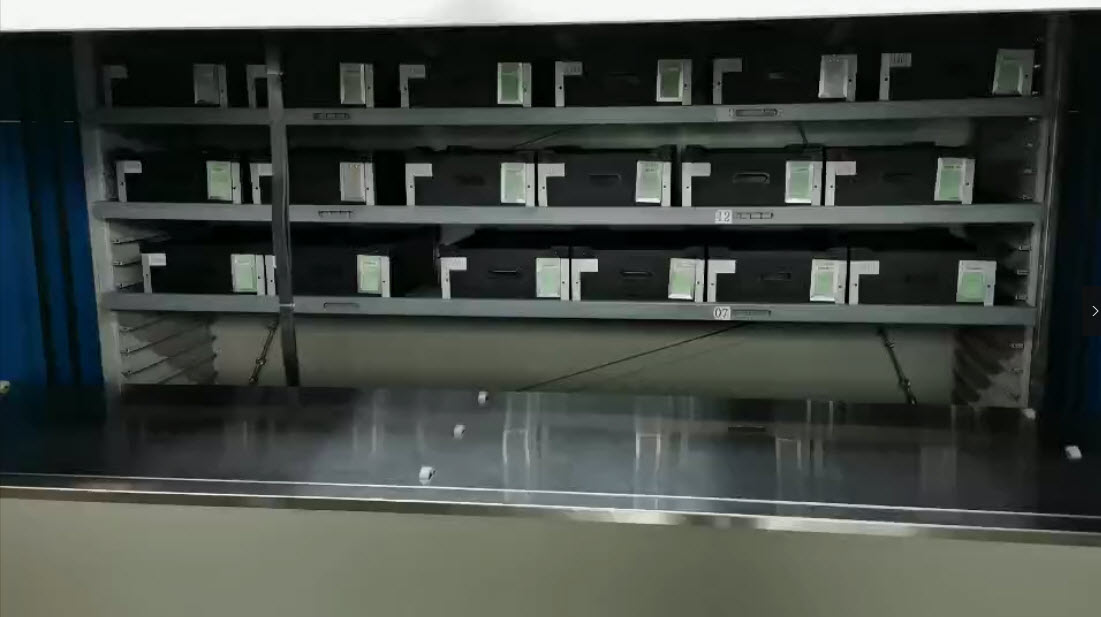

(The above picture shows a customer's warehouse, with a total area of over 4000 square meters, including a flat stacking area and 26 rows of high-position forklift shelves. The inventory is large and complex.)

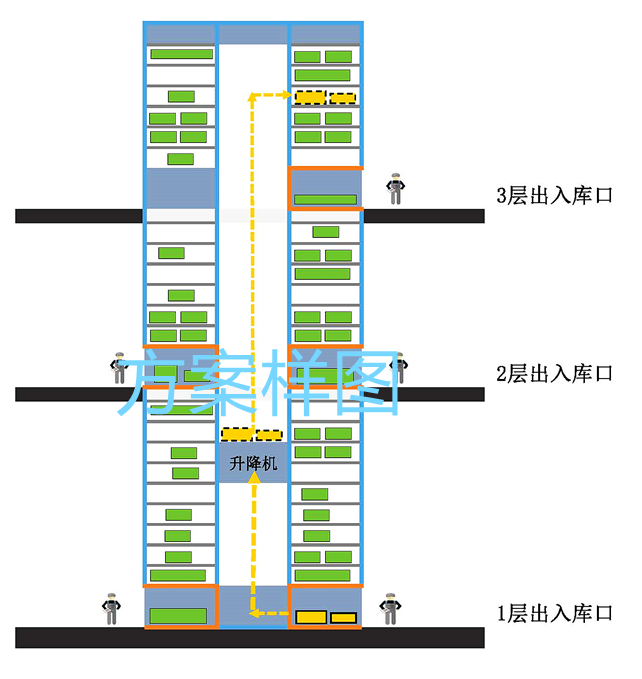

It's time to introduce intelligent warehousing equipment to the customer's warehouse! It is fully automated and has no need for manual handling. Our vertical lift module only requires 12 square meters, which is equivalent to storing up to 100 square meters of materials in a flat warehouse. The height of the vertical lift module can reach up to 24 meters. And AS/RS can help you realize fully automated intelligent inventory management- Once the inventory time is set on WMS software, the inventory operations can be quickly carried out. By using intelligent warehousing equipment, combined with easy-to-use WMS software, the company's inventory work is no longer cumbersome.