Design of vertical lift modules crossing floors

The customer is a manufacturing enterprise in the electronics industry, with over a hundred types of materials entering and exiting every day. Although AGV delivery vehicles have been introduced, they cannot meet actual needs. The daily delivery and turnover efficiency of warehouse employees have become a pain point of the customer.

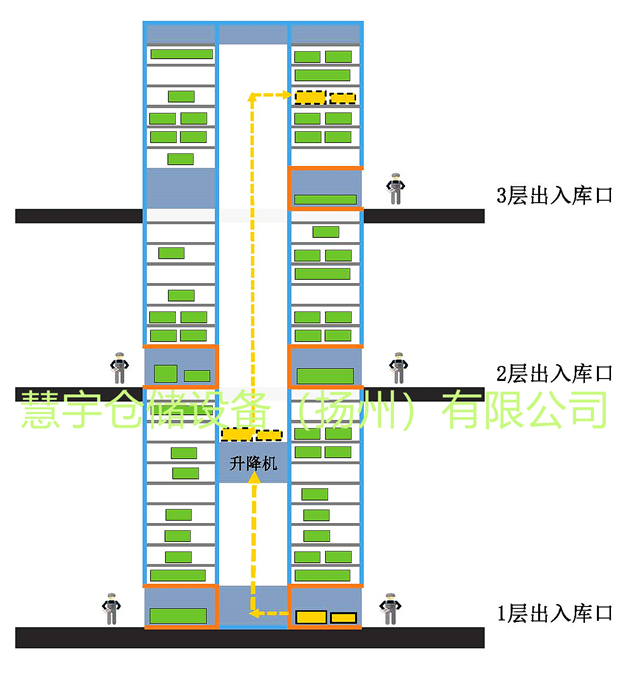

The receiving department of the customer's warehouse is on the first floor, the production department is on the second floor, and some semi-finished products are piling up in the plane area of the third floor. Our company's design of vertical lift module can meet the needs of customer for material delivery requirements between floors.

In the solution, we designed two vertical lift modules which are capable of passing through floors, each module is equipped with 152 trays and a single tray load is 350kg. A work port was set up on each floor, each with five workers sorting materials, it is convenient for the turnover of materials and semi-finished products between 1-3 floors.

The vertical lift module is equipped with full-function WMS software, which automatically sends materials to the sorting port on the designated floor according to the requirements, thus achieving automation, intelligence, and faster material turnover. It also helps store more goods in limited three-dimensional space, reduce flat stacking areas, and accelerate the efficiency of sorting and distribution.

The following is a diagram of the vertical lift module designed by HYMAT Ltd for customer: