Introduction of WMS(Warehouse Management System) software - HYMAT Ltd

1. Overview

The AS/RS software system is mainly used to manage warehouse data and control the operation of equipment. It has functions such as real-time monitoring, querying historical tasks and so on. The real-time graphical monitoring function can display alarms, locate alarms, and view alarm information, with friendly UI interface. The development method of the system software is object-oriented, which adopts structured and modular analysis and design, and emphasizes the principles of optimization, innovation, practicality, efficiency, and stability.

2. the overall software composition in general projects

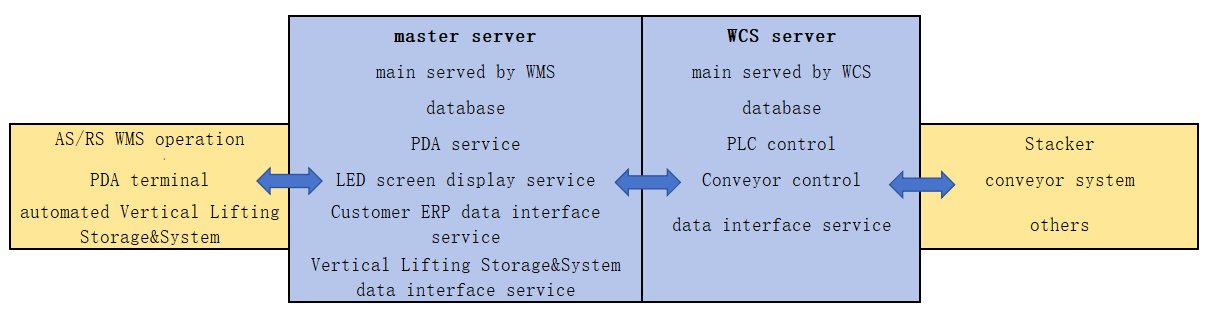

The operation and control software system of AS/RS mainly includes three parts: warehouse management system (WMS), warehouse control system (WCS), and handheld PDA software.

WMS: is responsible for the processing of warehousing business logic, including basic warehouse, materials, trays, inbound and outbound, inventory management, etc.

WCS: is responsible for coordinating and scheduling various underlying devices, enabling them to execute the business processes of WMS, and this process is completely performed according to the preset procedures of the program.

PDA: the mobile data processing terminal used by the operator.

3. Design principles

For efficient software engineering, good design is crucial. A well-designed software system should be straightforward to implement and easy to maintain, easy to understand, and reliable.

a. The design is traceable.

b. The design shows consistency.

c. The design has scalability, with upgrade interfaces and upgrade space.

4. WMS Software Functions

1) Basic Data Management

- User Management

- Warehouse keeper management

- Data Configuration

- Data Backup

- System Configuration

2) Warehouse Management

- shelf information

- location information

- cargo area management

3) Tray and Material Management

- Material Type Management

- Material Management

- Tray Type Management

- Tray Management

- Tray location information

4) Bar code

- Barcode information

- Display Task Information

5) storage and retrieval management

- Inbound/Outbound Type (Purchase Inbound, Replenishment Inbound, Order Outbound, Picking Outbound...)

- Inbound and outbound orders

- Inbound and outbound task

- ASN inventory management (if the customer has an ASN operation mode)

- Material calling management

6) Inventory Maintenance

- Inventory Status Management

- inventory inquiry (date, batch number, item, inventory status...)

- transfer (if the customer has transfer needs)

7) Report Query

- Inbound Report

- Outbound Report

- Inventory Report

- Inventory statistics report

- etc.

8) Task Management

- Manage tasks that have already been issued

- Monitor tasks that have already been issued

9) PDA Handheld Terminal

- auxiliary operations (inbound, outbound, sorting, inventory, data query...)

10) Customized Modules

- ER Pinterface docking

- data synchronization

- etc.

5. software implementation

requirement confirm - project design - scheme confirm - software function research - software framework design - customer function confirm - software testing - installation and debugging - on-line operation

6. WMS Software Architecture

Using the latest B/S software architecture, users in the LAN can access the server through the browser and operate according to their permissions.

7. stocktaking

The inventory list is issued by the ERP system, and the WMS executes the inventory plan according to the time selected by the customer; the overall plan is executed by the customer on the WMS.

The stocktaking list is issued by the ERP system, and the WMS software executes the stocktaking plan based on the time selected by the customer. The overall plan will be executed by the customer on WMS.

8. system structure

9. special situation processing

Power Outage: UPS Support

Local/Wireless Network Failure: manual handling

WMS, WCS fault: manually input parameter operations at the terminal

Server failure: using backup data for recovery